The Quest for Purity in Liquid Gold: A Comprehensive Comparison of Olive Oil Filtration Options

- fethi çelik

- Oct 1, 2025

- 5 min read

Olive oil production is a meticulous art, from harvest to pressing. However, this art doesn't end once the oil leaves the press. There's a final, critical step that determines the character, quality, flavor profile, and durability of extra virgin olive oil: filtration.

The crude oil obtained when olives are pressed is not pure. It contains suspended micro-olive particles, pulp (sediment), and some vegetal water. These components give the oil a cloudy appearance. Filtering is the process of removing these unwanted substances from the oil. So, how necessary is this process? Is unfiltered olive oil, which has become popular in recent years, healthier, or is filtering a necessity to maintain quality?

In this article, we will examine olive oil filtering options, from traditional methods to the most modern technologies, comparing their advantages, disadvantages, and effects on the final product.

The Science Behind Filtering: Why It's Necessary

The primary purpose of filtration is chemical rather than aesthetic. Water and organic particles in raw olive oil are its natural enemies.

1. Enzymatic Activity and Hydrolysis: Pulp and water contain active enzymes. In the presence of water, these enzymes break down triglycerides (the main component of oil), resulting in the formation of free fatty acids (hydrolysis). As acidity increases, the quality of the oil decreases and it may lose its "extra virgin" character.

2. Oxidation: Water and sediment accelerate oxidation by allowing the oil to come into contact with oxygen. Oxidation causes rancidity and destroys beneficial vitamin E and antioxidants.

3. Fermentation: Organic matter can ferment over time, leading to serious sensory defects such as "muddy sediment," "mold," or "vinegariness."

In short, filtering removes these spoilage catalysts, improving the stability of the olive oil and extending its shelf life.

Nature's Raw Form: Unfiltered Olive Oil (Olio Nuovo)

Unfiltered olive oil ( Olio Nuovo in Italian) is oil that has not undergone any significant mechanical filtering after pressing. It is cloudy, dense, and often has a vibrant color.

The appeal: Unfiltered oils offer all the intensity and fruitiness of fresh-pressed oils. Thanks to their micro-particles, they may initially have a higher polyphenol (antioxidant) content. This can lead to a stronger bitterness and pungency.

Risks: This appeal is short-lived. Unfiltered oils spoil very quickly due to the moisture and sediment they contain. Initially high polyphenol levels decline rapidly due to accelerated oxidation. Unfiltered olive oils should ideally be consumed within the first 3-6 months. They are not suitable for long-term storage.

An In-Depth Look at Olive Oil Filtering Methods

Filtering methods vary depending on the technology applied and the desired result.

1. Traditional Method: Natural Decantation (Settling)

It's the oldest and gentlest refining method. It's not a filtration process, but a gravity-based separation process. Fresh oil is collected in tanks, and the pulp is allowed to settle to the bottom. The clearer oil at the top is carefully separated from the sediment.

Advantages: It is natural, low cost and is the method that least interferes with the original character of the oil.

Disadvantages: Time-consuming (can take weeks/months). Does not provide complete clarity, and microparticles and some moisture remain in the oil. Shelf life is shorter than mechanical filtration.

2. Mechanical Filtration Methods

In industrial production, mechanical methods are preferred for speed and efficiency.

a. Cotton Filters

It's a simple and traditional method. The oil is filtered through layers of cotton. The cotton retains moisture and particles.

Advantages: Easy and inexpensive to install. Suitable for small-scale producers.

Disadvantages: Low efficiency. Hygiene is difficult to maintain; cotton can leave an odor in the oil if not cleaned properly. Labor-intensive.

b. Plate and Frame Filters (Cardboard/Cellulose Filters)

This is the most widely used industrial method. Olive oil is passed through filter plates made of cellulose or cardboard under pressure.

Advantages: Fast, effective, and suitable for high-volume production. Provides excellent clarity. Highly cost-effective.

Disadvantages: In open systems, there's a risk of oil coming into contact with air (oxidation). Regular filter plate replacement requires additional cost and labor. Too strict filtration can retain some of the polyphenols and aromas.

c. Diatomaceous Earth (Kieselguhr) and Perlite Filters

This method uses diatomaceous earth (Kieselguhr), a fossilized algae, or perlite, a volcanic material, as a filtering aid. This material forms a filter cake on a surface, and the oil is passed through this cake.

Advantages: Retains very fine particles, provides a crystal-clear appearance. Allows for high flow rates.

Disadvantages: High initial investment and operating costs. Care is required in the use and disposal of filter aids. Because it is an aggressive method, it can adsorb more beneficial components.

3. Modern and Advanced Techniques

With the advancement of technology, more efficient and protective methods have been developed.

a. Lenticular (Module) Filters

It is an advanced version of plate filters. The filtering elements are in modules housed in a closed stainless steel housing.

Advantages: Thanks to the closed system, air contact is minimal, reducing the risk of oxidation. It is hygienic and leak-proof. Filter replacement is easy.

Disadvantages: Initial investment cost and module costs are higher than plate filters.

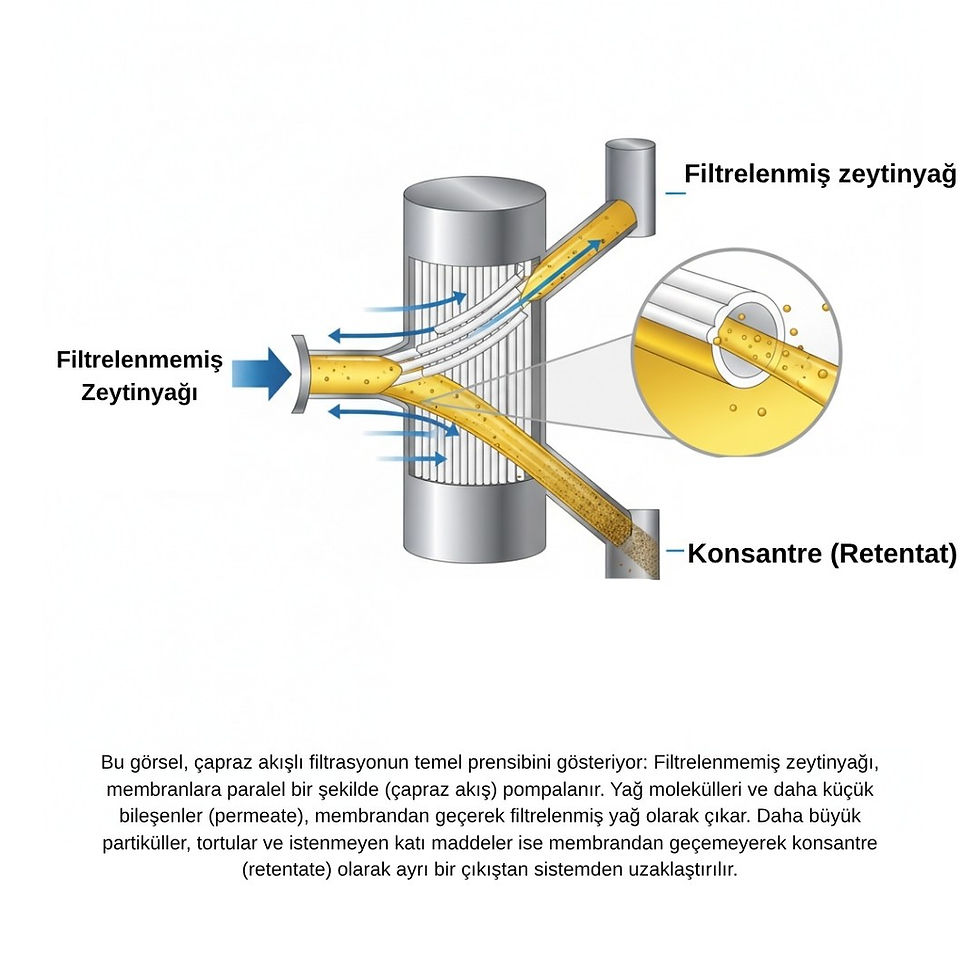

b. Cross-Flow Filtration

It's one of the most advanced technologies. Oil is circulated at high speed, parallel (diagonal) to a membrane surface. As the oil passes through the membrane due to pressure differences, particles are trapped on the surface and carried away by the flow, preventing membrane clogging.

Advantages: Provides excellent stability and clarity in a single pass. No filter aid required (low waste). Closed and automatic system. It's the modern method that best preserves the oil's chemical and sensory properties.

Disadvantages: Requires very high initial investment. Requires technical knowledge and expert maintenance.

Comparative Analysis: Effects on Quality

The choice of filtration method depends on the producer's understanding of quality and objectives.

Polyphenols and Health: The Stability Paradox

A common misconception is that filtering is detrimental to health. While unfiltered oils may initially have higher polyphenol content, these compounds degrade rapidly in an unstable environment. Filtration may initially cause a small loss of polyphenols (especially with aggressive methods), but it increases the oil's stability, protecting the remaining polyphenols from oxidation. Consequently, after six months of pressing, filtered oils generally have higher polyphenol levels than unfiltered oils.

Flavor Profile and Aesthetics

Unfiltered oils are more intense, aggressive, and fruity. Filtering gives the oil a more balanced, clean, and elegant flavor profile. The vast majority of consumers prefer aesthetically clear and bright oils.

Cost and Efficiency

Speed is essential for large-scale producers. Plate filters offer a cost-effective solution, while Kieselguhr offers high efficiency. Cross-flow systems, despite their high initial cost, can offer low long-term operating costs. Decantation is the cheapest but slowest method.

Conclusion: Finding the Ideal Balance

There's no single "right" method for olive oil filtration. The choice depends on the producer's philosophy, production volume, and target product type.

If the goal is a seasonal "nectar" with an intense flavor that will be consumed in a short time, natural decantation or unfiltered presentation may be preferred.

If the goal is a high-quality product that is stable, has a long shelf life, balanced and appeals to a wide audience, modern systems such as plate filters , lenticular filters or cross-flow filtration are the most suitable options.

While filtration compromises the initial enthusiasm of olive oil, it is often an essential quality control step to ensure that this liquid gold retains its quality, flavor, and health benefits for a long time.

Comments